Our Mission...

to provide professional educational programmes

and comprehensive technical & operational assistance

Equipment Audit

APEGG offer audit & inspection services, which are pro-active ‘tools’ towards identifying potential problems at an early stage, minimising the risk of unexpected problems and failure together with extending the life expectancy of equipment.

Examples of areas which APEGG can audit:

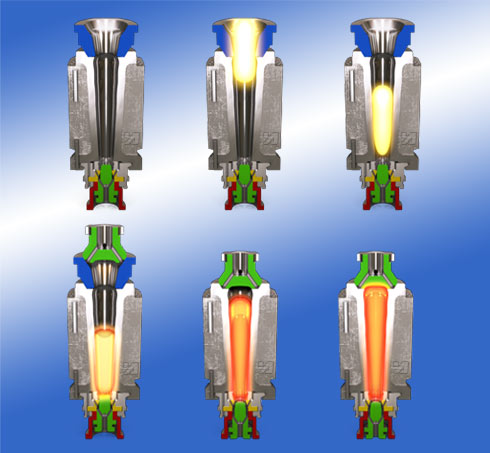

Furnace & Forehearth: Furnace operation and efficiency audits are important to extend the life expectancy and to keep energy costs as low as possible. APEGG’s audit programs include visual structural, thermal imaging and endoscopy assessment of these systems.

Forming machine: Checking forming and Hot End equipment on a regular basis provides the best basis for a low downtime operation. APEGG guide customers to maximise the lifetime of the equipment and keep machine availability time up.

Inspection, packaging: These areas must be in top condition at all times, reliable container inspection and packing is of paramount importance for a successful glass manufacturing plant. Audits from APEGG in this area help to keep the equipment in good condition.

Thermography: APEGG offer a thermography audit for all major electrical components throughout the plant, including cooling fans and compressors. These audits are very useful, not only to keep the equipment running, but also to reduce the risk of fire caused by faulty equipment.

Regular audits on all the production equipment from furnace to palletizer can highlight potential issues and with this maintenance work can be planned. It is APEGG’s aim to guide customers from a repair to a maintained mentality, as this can help avoiding unwanted downtime.

These audits can be part of a production & technical assistance program. To discuss further details about this service, please contact us.