Our Mission...

to provide professional educational programmes

and comprehensive technical & operational assistance

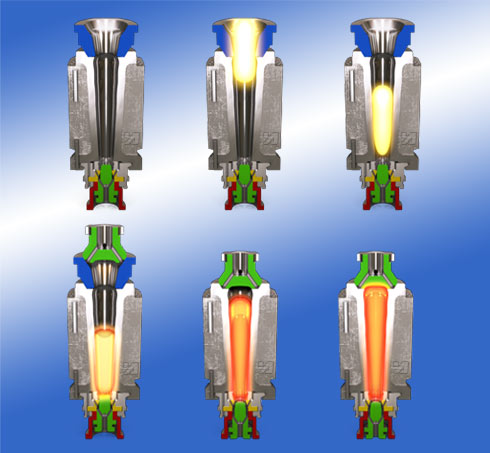

Mould Design Review

This is a unique trouble shooting service offered by APEGG.

In the event that a container is not performing, APEGG have the knowhow to assess existing mould design drawings in order to improve the production process. It is always our aim, where possible, to use existing mould gear. If modifications are not practically APEGG can offer a complete redesign of the equipment. See mould design.

For the trouble shooting we follow the 3 steps:

Assessment: APEGG will discuss with the glass manufacturer or filler the performance issues with the container in question, e.g. low bursting pressures, impact failure etc. The production data such as feeder set-up, machine set-up, speed, quality control, packaging will be analysed.

Review: The complete mould design will be studied in conjunction with the production/quality data. This information will be compared with the APEGG standards for mould design and based on the findings a recommendation for modification will be put forward.

Modification: The glass manufacturer can carry out the modifications requested by APEGG directly or APEGG can assist with the equipment alteration.

APEGG offer in addition, mould design training to the relevant personnel.

We are proud to say that we were able to help different customers around the globe with the improvement of their existing designs, which shown positive impact on production efficiency. Customers can send us their design for an initial free pre evaluation, for details please contact us.

To read the latest information about this service, go to Glass Open Book