Our Mission...

to provide professional educational programmes

and comprehensive technical & operational assistance

Forming Training

APEGG provide forming training for the different forming processes such as Blow & Blow (BB), Press & Blow (PB) & Narrow Neck Press & Blow (NNPB). Training is provided in classroom environment and hands on. We offer standard and tailored training programs to customers around the globe.

Example of training topics:

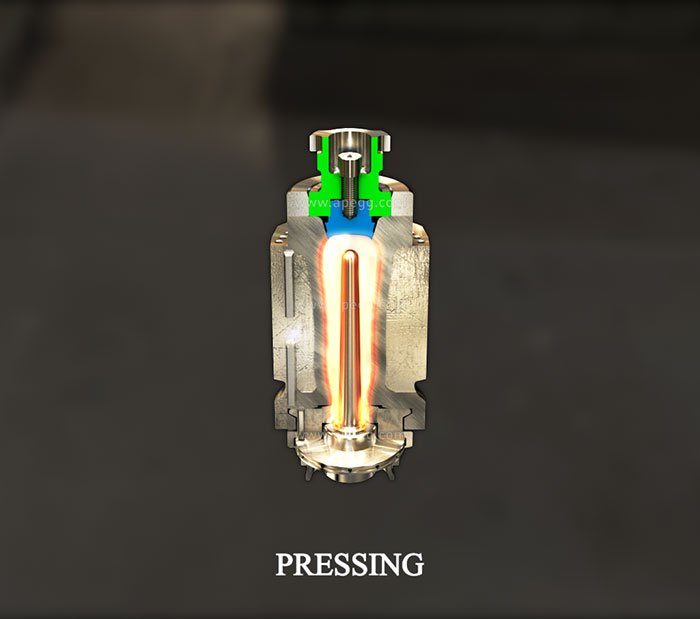

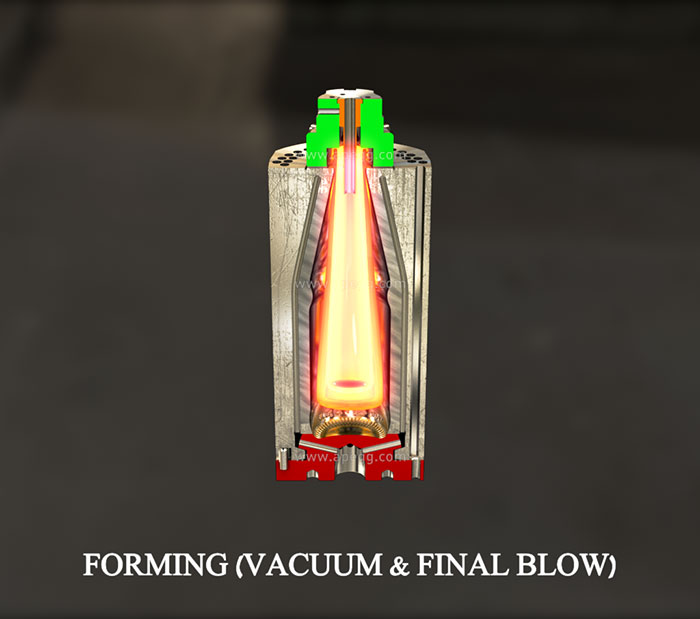

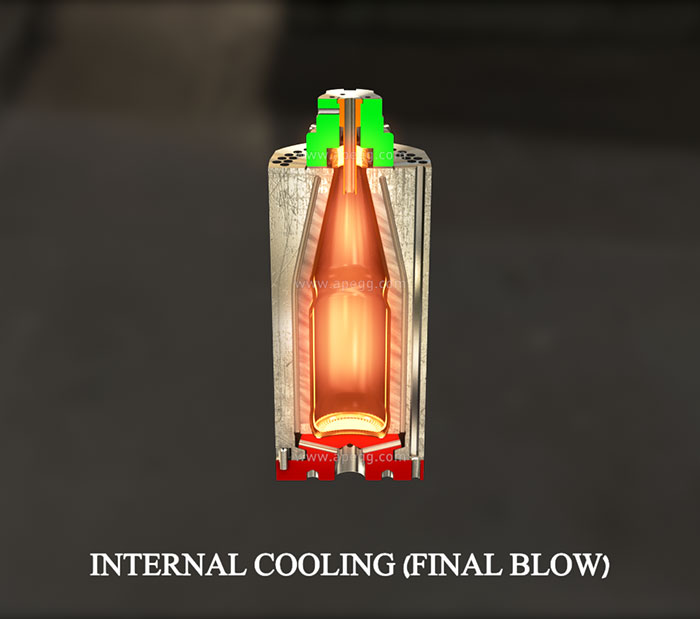

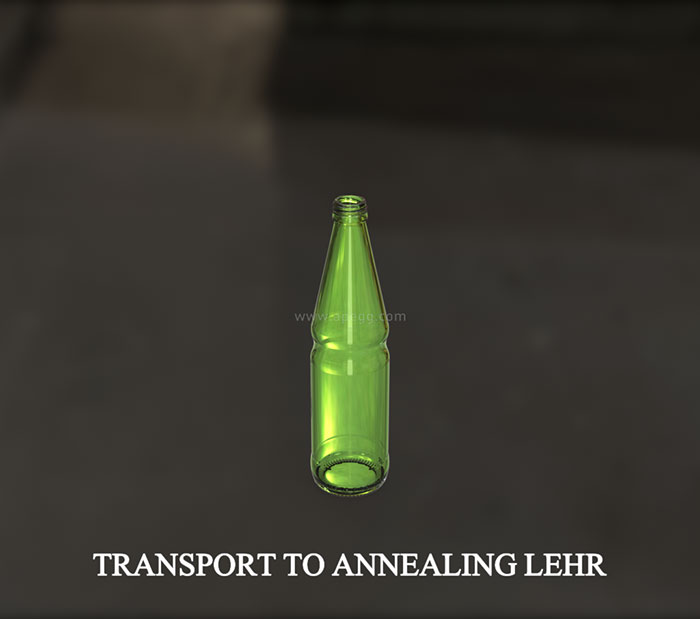

Process: Glass containers are manufactured with different forming processes, such as BB, NNPB and PB. As a first step it is good to understand the characteristics of each process and to know what equipment is used in each (e.g. what mould gear, IS machine accessories etc.

Gob forming: Successful production can only be achieved with the correct glass gob, that’s why APEGG start every forming training at this point. Here we discuss every aspect required to make the ‘perfect’ gob. The loading of the gob into the blank will also be covered.

Set-up: A forming machine must be set-up correctly in order to produce high quality glass containers. Both the mechanical and the timing set-up have to be 100% correct to provide a stable basis for production. Often defects are introduced through bad set-up of forming machine and associated equipment.

Timing: Today it is required that each article is produced at the maximum production speed (bottles per minute). This requires a perfect set-up and optimisation of the machine timing. APEGG offer advance training for timing optimisations.

Machine operation: The production of glass containers is a 24/7 process, where machine operation play’s a very important part in sustaining high efficiencies. APEGG provide training for machine operation, e.g. swabbing of moulds, quality checks, defect detection and remedies.

Job change: From time to time the forming machine needs to go through a ‘job change’ to allow the production of a different glass container. APEGG offer basic and advanced job change training especially for companies with multiple job changes. A job change can be very costive for a glass container producers, APEGG can guide glass manufacturers to optimise job changes and with this increase profit.

Training programs from APEGG are tailored for any customer, which makes us unique in the way we provide the training. To discuss the details for your training program, please contact us.

To read the latest information about this service, go to Glass Open Book