Our Mission...

to provide professional educational programmes

and comprehensive technical & operational assistance

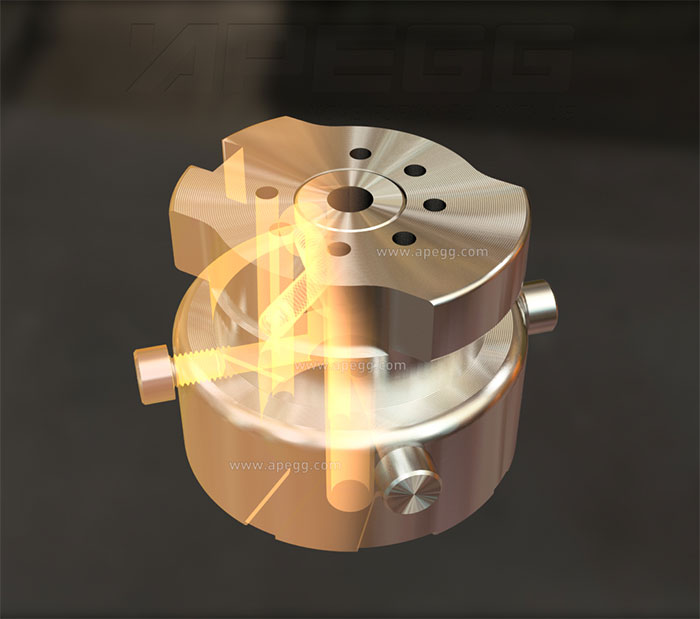

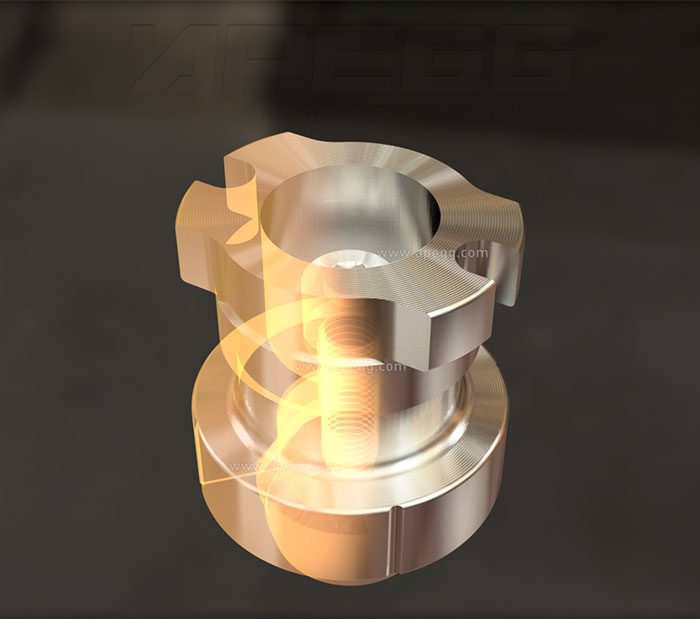

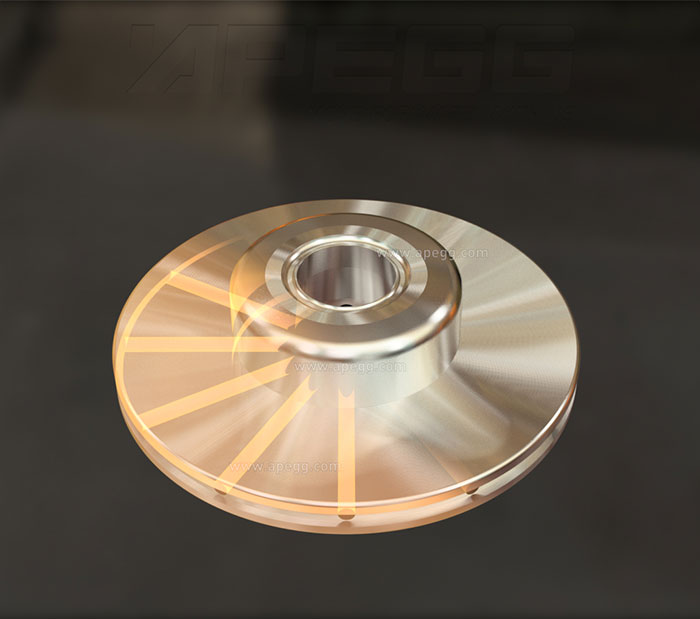

Mould Inspection & Repair Training

Successful glass container production is dependent on well-maintained mould equipment.

Not only the actual container quality is influenced by the mould equipment, it has a direct impact on the manufacturing costs. APEGG provide advance training for existing companies to improve mould repair and for new companies to set up the correct mould repair philosophy.

Audit: As a first step APEGG audit the mould shop set-up/operation and the quality of repaired mould equipment. The submitted audit report will provide the frame work for the actual training programme.

Training: Based on the audit results APEGG will tailor a training programme suitable for the customer. For new customers the training will start with the basic requirements for mould repair.

Mould inspection: Inspection is a very important part of the mould department. Not only repaired mould equipment must be audit, new received equipment must also be inspected.

Mould equipment which is kept at a high standard reduces forming defects and increases the life expectancy of the mould equipment. APEGG provide training and Standard Operating Procedures (SOP’s) for mould inspection and repair. APEGG can in addition offer classroom and hands on training in the UK.

If required APEGG can also provide mould equipment repair in the UK e.g. half-life repair.

To discuss your requirements, please contact us

To read the latest information about this service, go to Glass Open Book